Symptoms

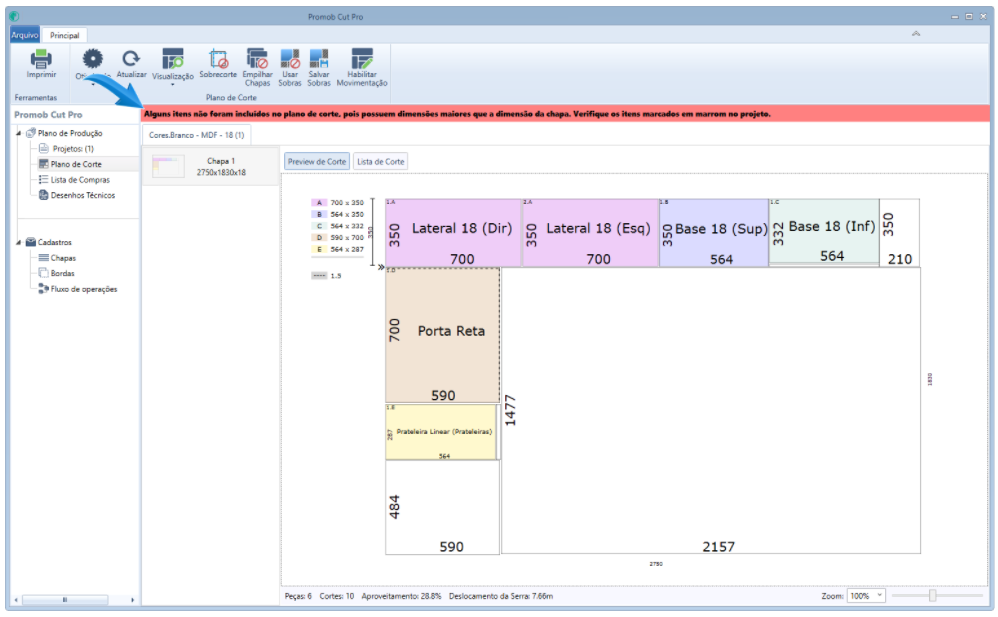

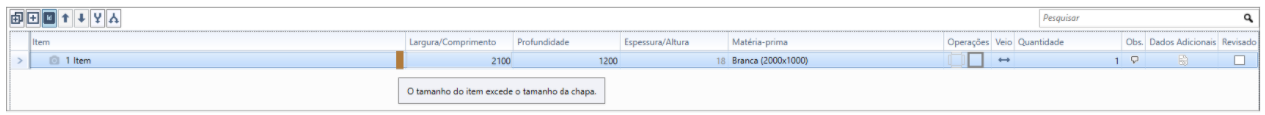

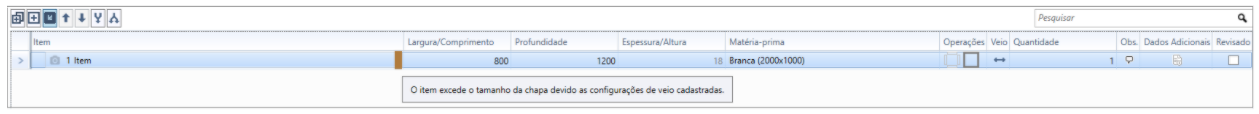

When accessing the Cut Plan, the message is displayed.

Causes

The situation may occur because:

1. The dimension of any part is greater than the maximum cutting size of the machine, (machine restriction);

2. The dimension of any part is greater than the dimension of the plate. Example: the width of the plate is 2750 mm and the width of the piece is 2900 mm (piece does not really fit on the plate);

3. The direction of the workpiece vein is changed, that is, the way the direction of the vein is configured, the workpiece does not fit on the plate and therefore cannot be cut;

4. Some plate has a registered refill. For example, the width of the piece is 2750 mm, (which would fit on the plate), but there is a profile registered on the plate, making the dimension of the piece larger than the dimension of the plate.

Solution

Solution 1: check maximum cut size

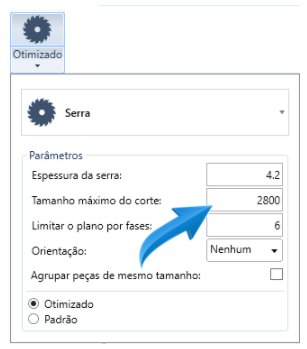

1. In the cut plan of the pieces, check the maximum cutting size of the machine that will be used for cutting the pieces.

2. Go to Optimized and check the maximum size that is registered.

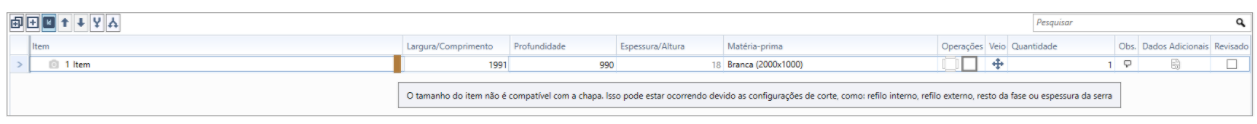

Solution 2: check dimension of parts

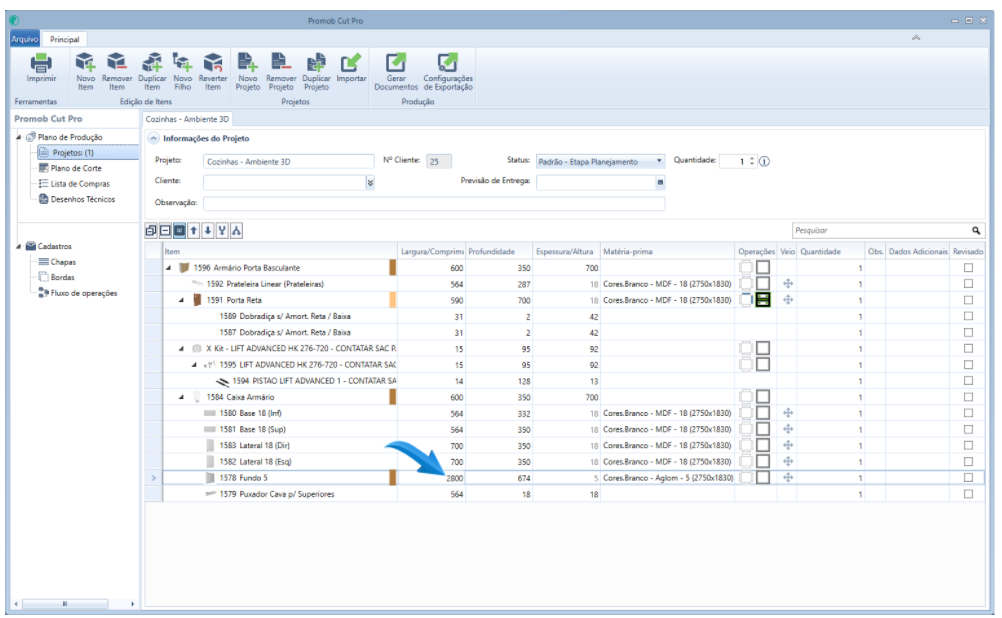

1. In Projects check the items identified by the brown color. Enter the value of the item's dimensions considering the maximum cut size or enter the correct value for this property.

Solution 3: change the direction of the plate shaft

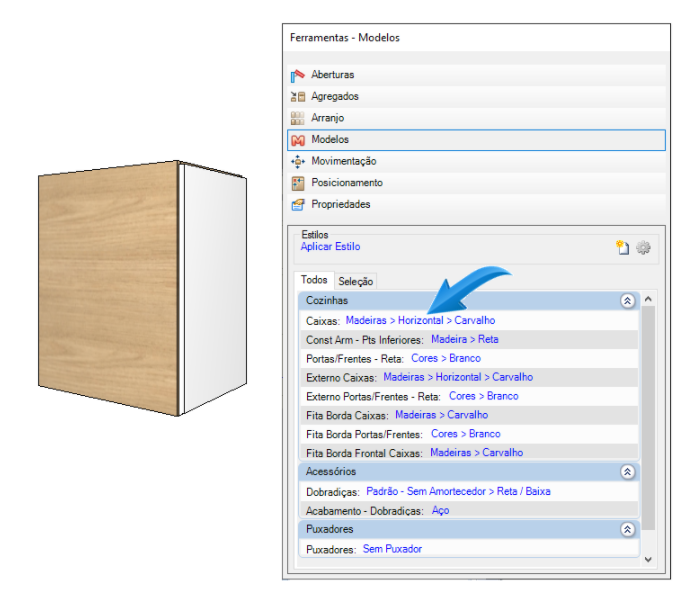

1. Change the direction of the material vein applied to the part. This change can be made in Promob or Cut:

- Change vein direction through Promob: select the module and access the Tools Panel - Models. If the model of the piece has a horizontal direction, select the model with a vertical direction and vice versa;

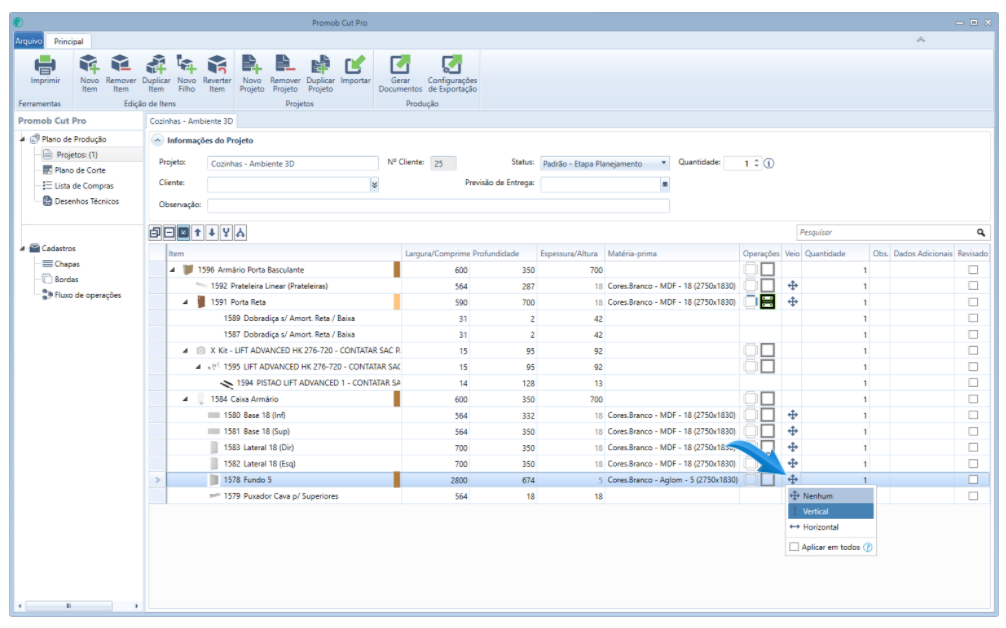

2. Change the direction of the vein through the Cut: in Projects, identify the part that is marked in brown, and in the Vein column, change the direction. If the vein direction is configured as horizontal, select the vertical direction and vice versa;

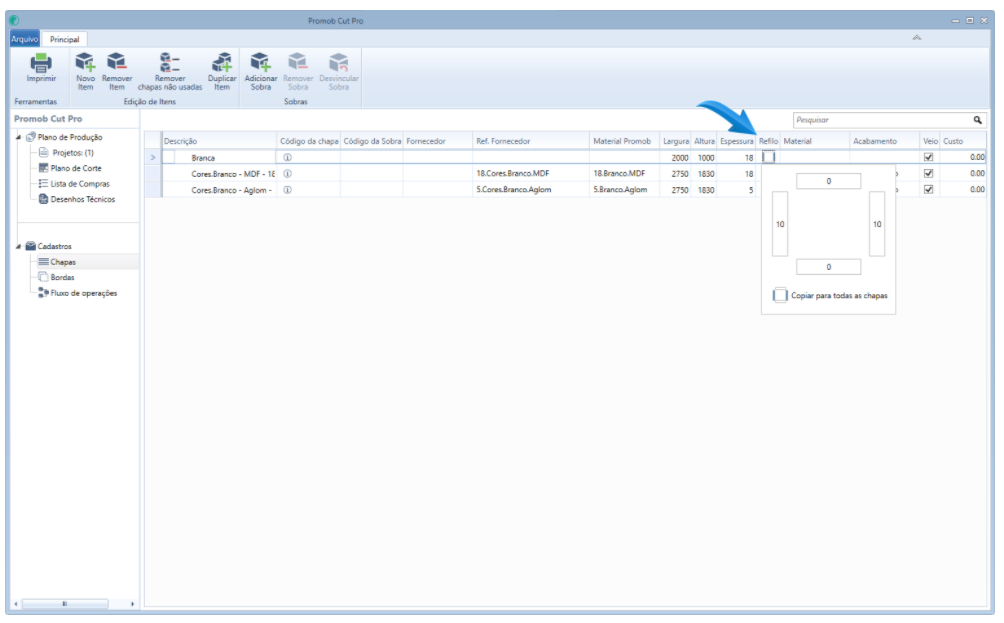

Solution 4: check the refill register on the plate

1. Access the plate register and check the registry value for the plate refills.