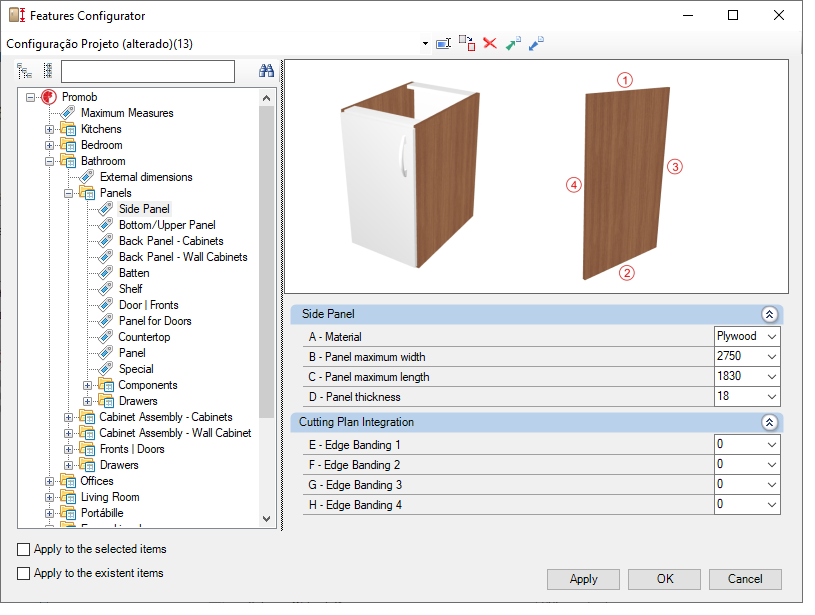

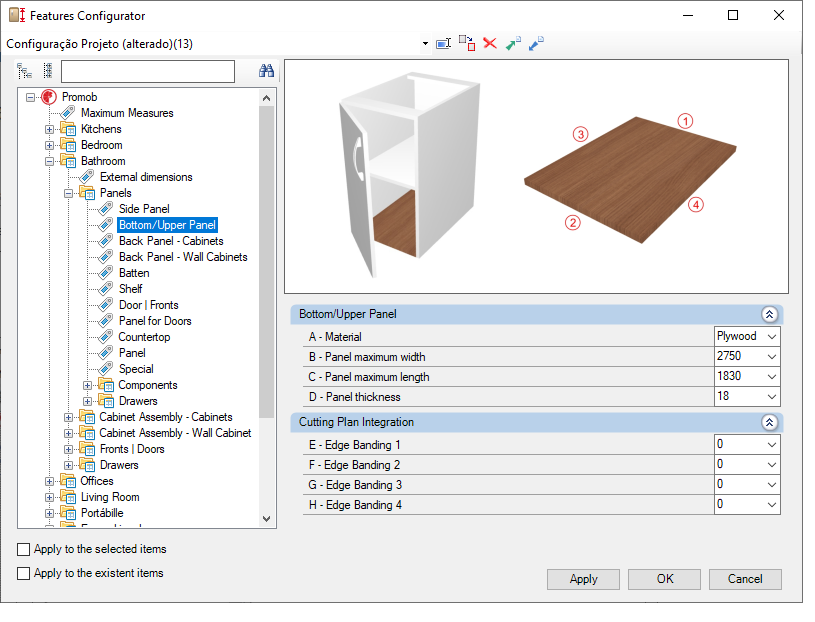

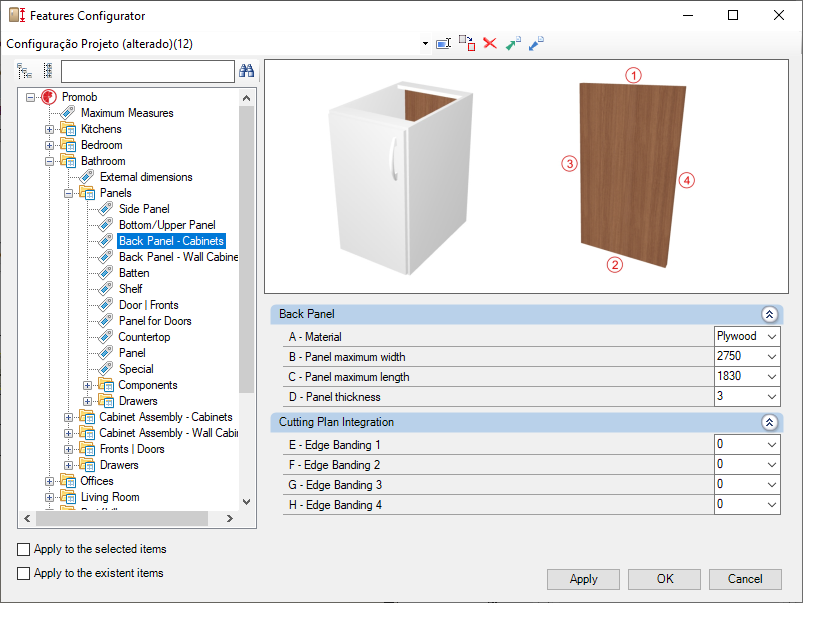

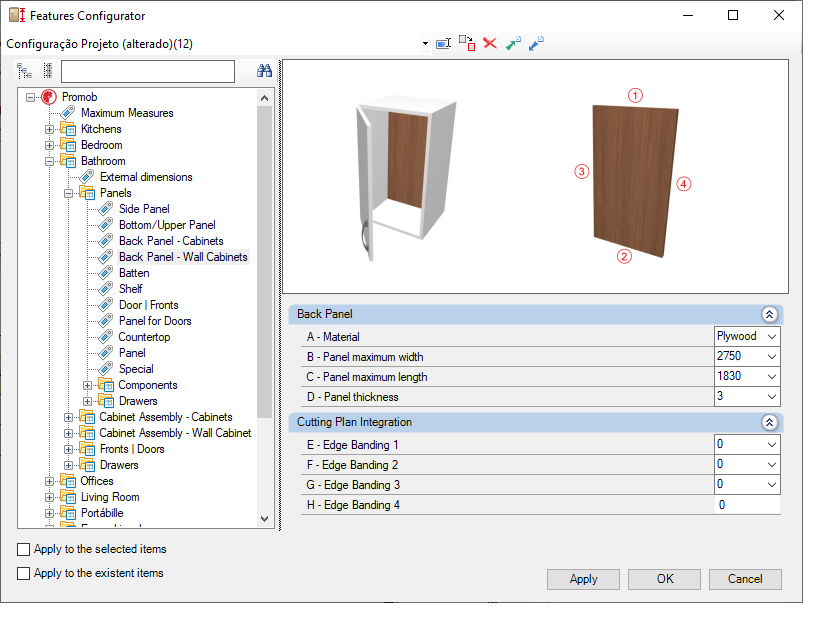

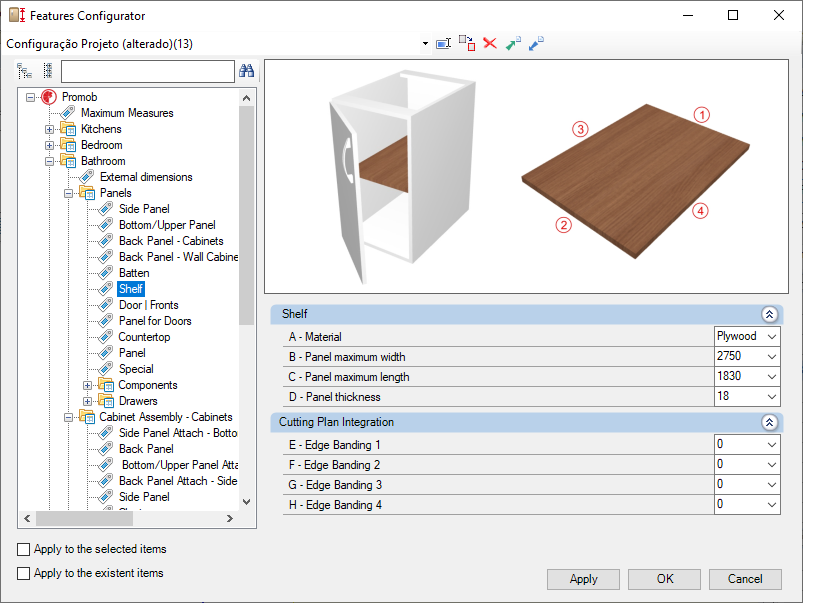

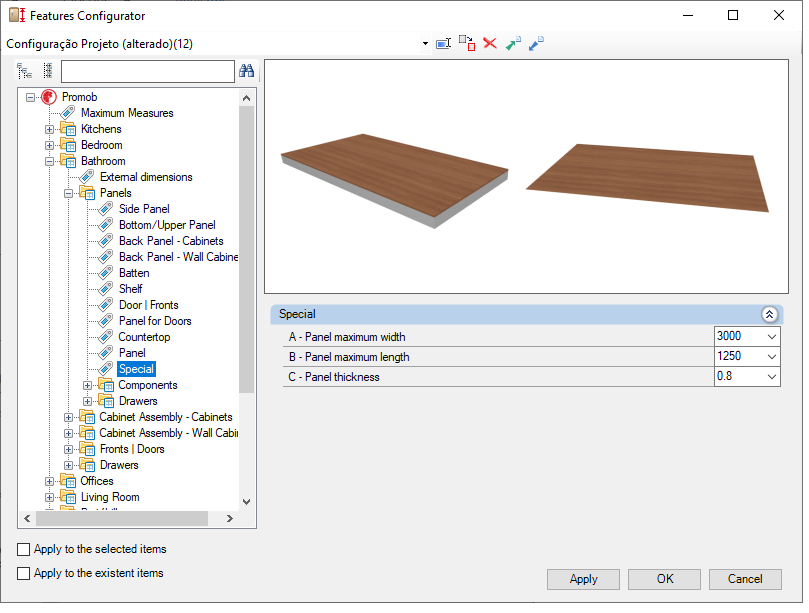

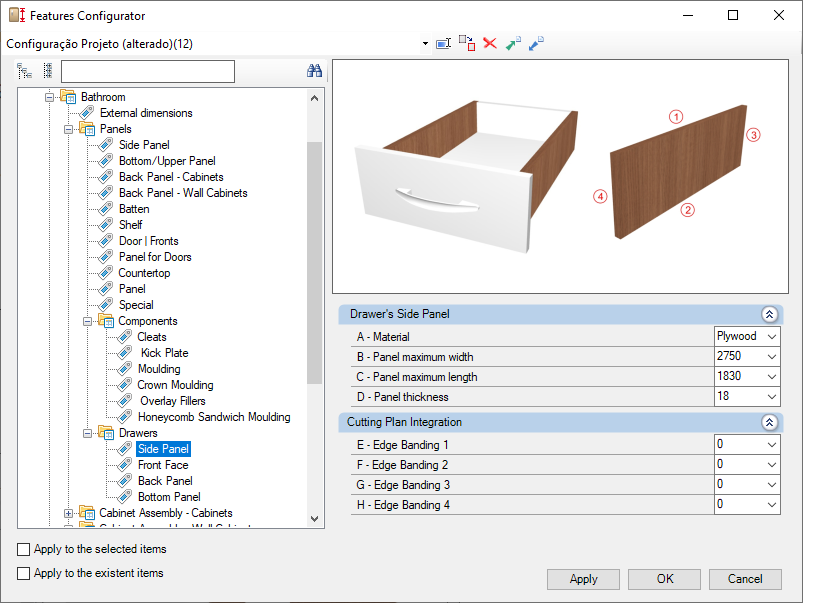

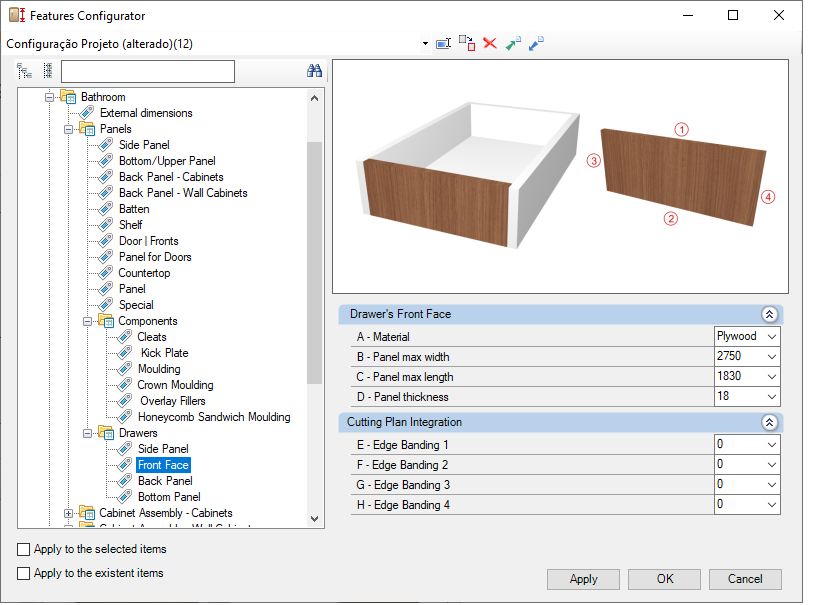

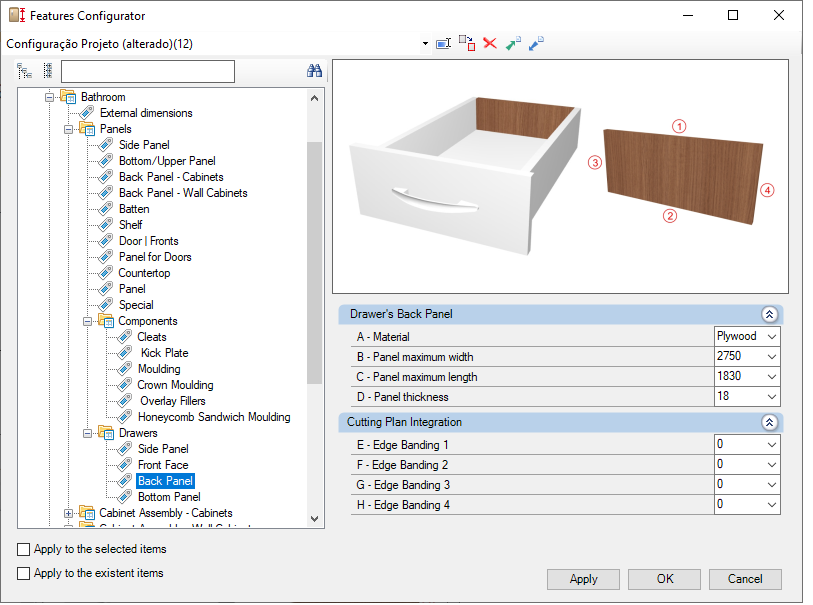

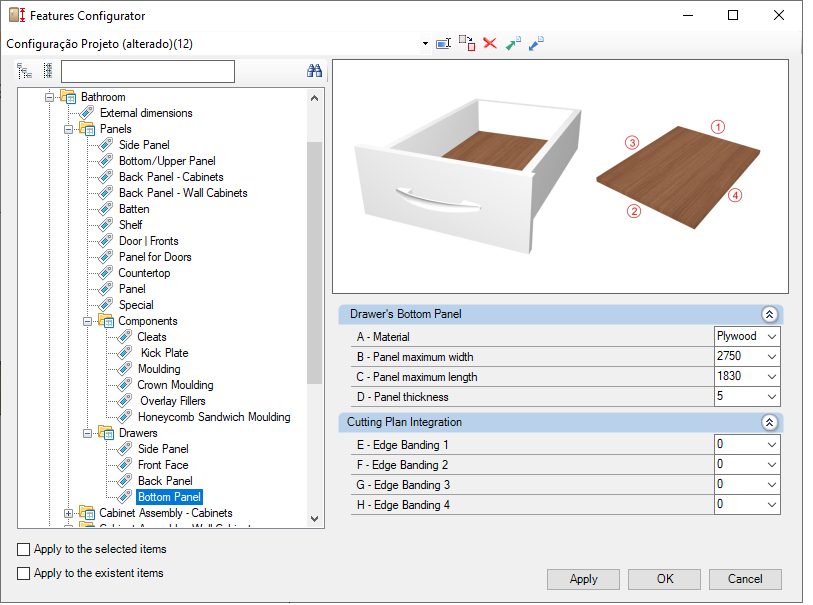

Check below, the definitions of each configuration available on Features Configurator - Bathroom - Panels. If necessary, see here how to apply the Features Configurations.

|

|

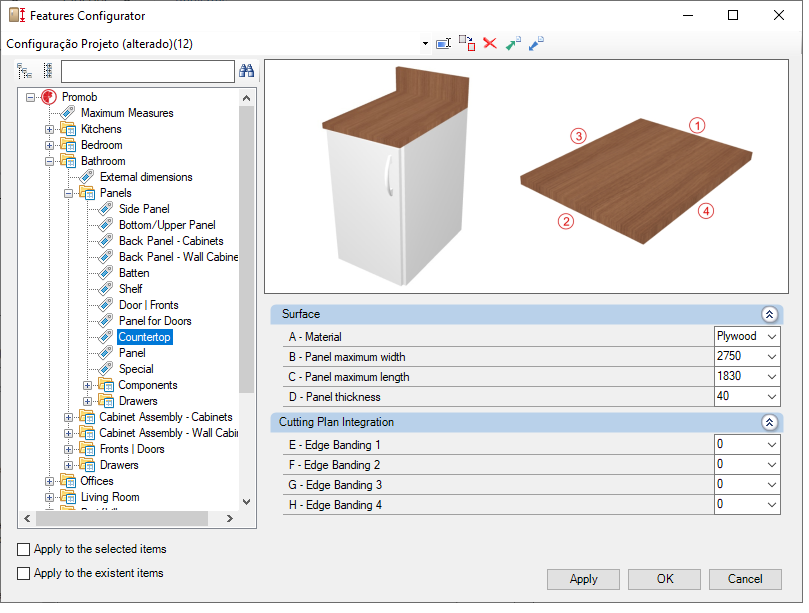

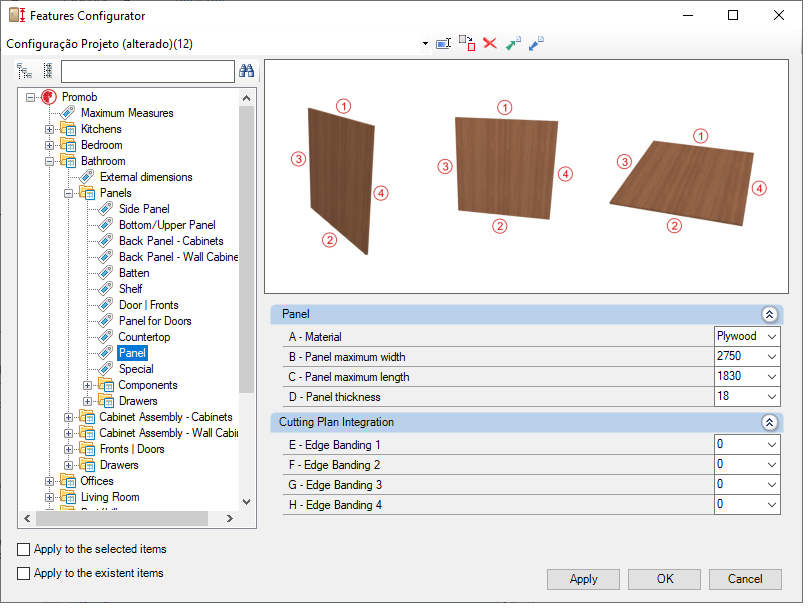

General Configurations

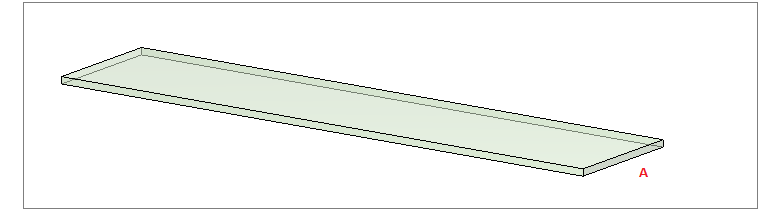

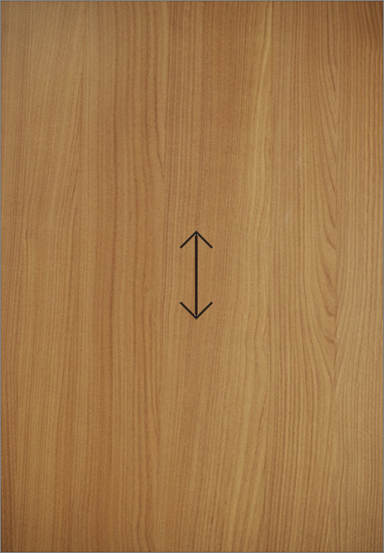

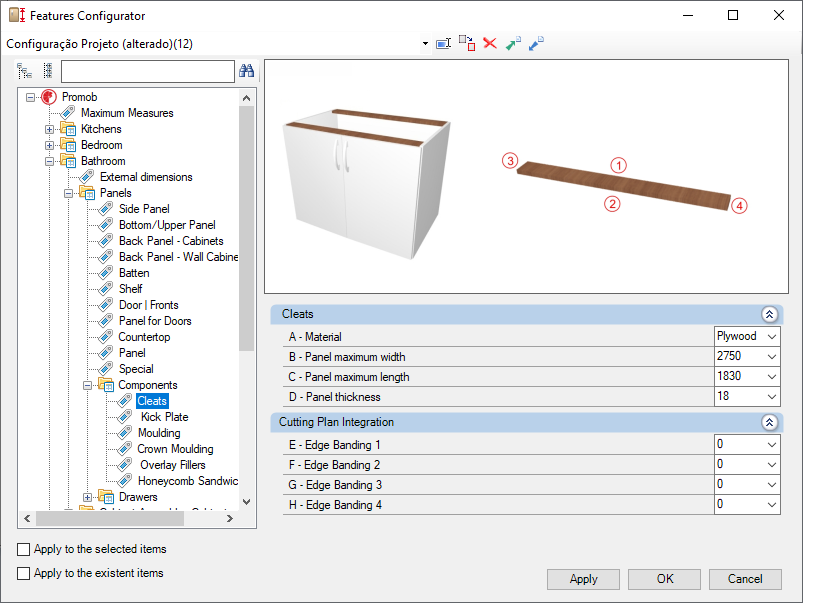

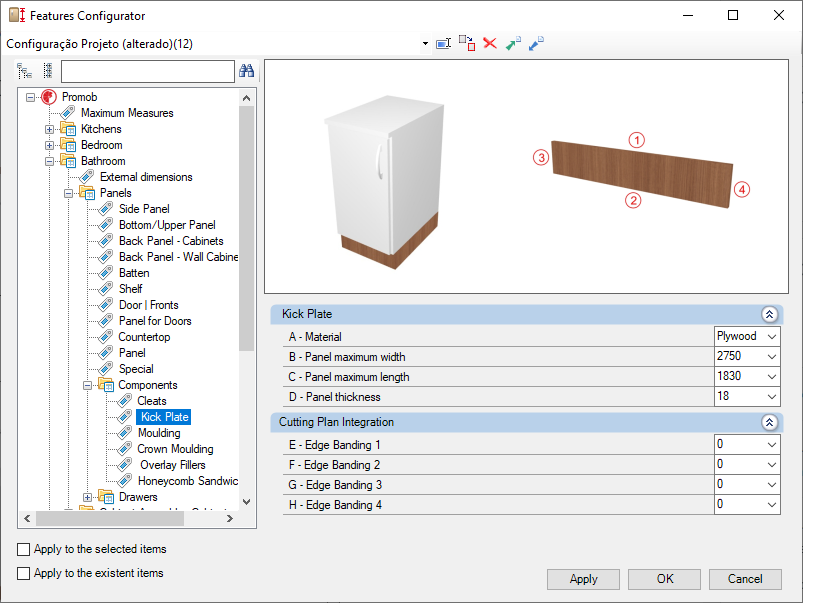

A – Material: defines the panel material to be used to manufacture the side of the module.

B – Panel maximium width: defines the maximum width of the panel to be used in the fabrication of the module side.

C – Panel Maximum lenght: defines the maximum plate length to be used in the manufacturing of the module's side.

D – Panel Thickness: defines the thickness of the plate to be used in the manufacturing of the module's side.

Side Panel

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

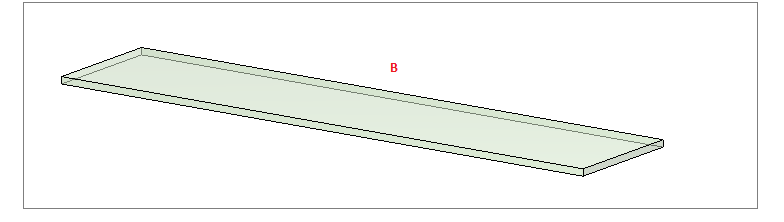

Bottom/ Upper Panel

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Back Panel - Cabinets

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Back Panel - Wall Cabinets

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3:for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

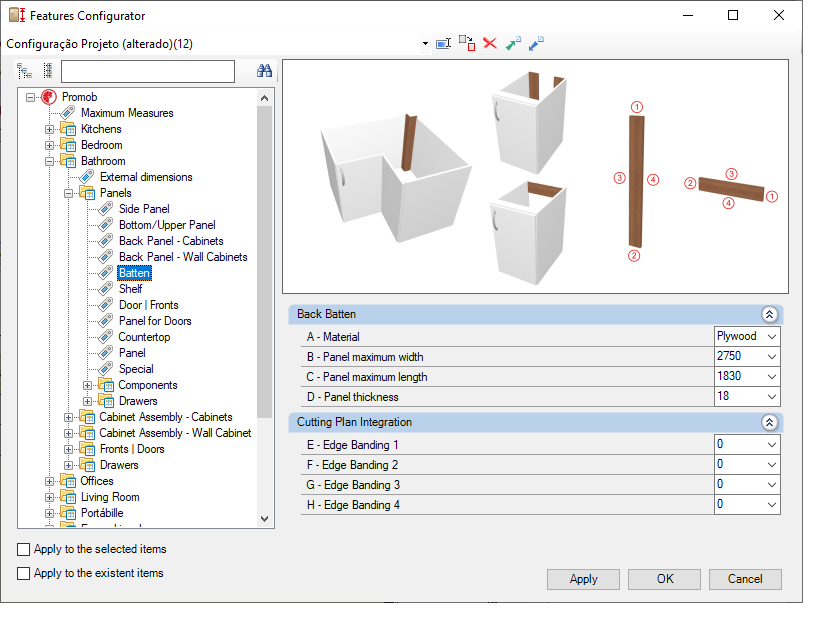

Batten

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G -Edge Banding 3:for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Shelf

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

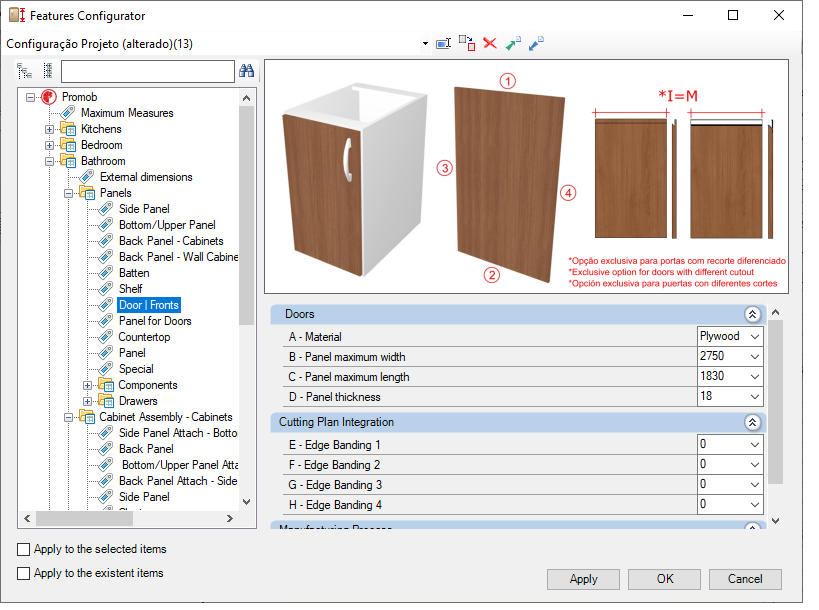

Doors | Fronts

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Manufacturing Process

I - Manufacturing Process Quantity: defines wheter the manufacturing process will be budgetedin units or in meters. Exclusive option for doors with different cutout.

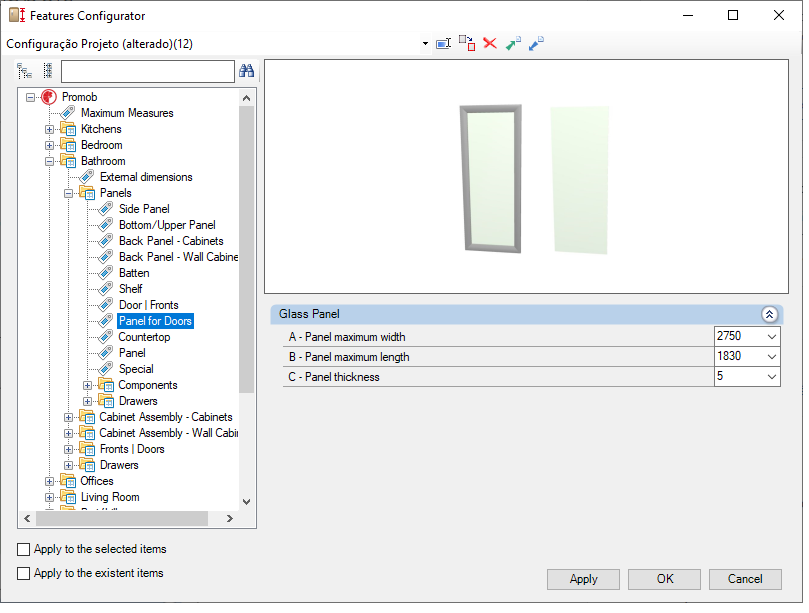

Panel for Doors

Glass Panel

A - Panel maximum width: defines the maximum glass width to be used in module manufacturing.

B - Panel maximum length: defines the maximum length of the glass to be used in the manufacturing of the module.

C - Panel thickness: defines the thickness of the glass to be used in the manufacturing of the module.

Countertop

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Panel

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3:for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

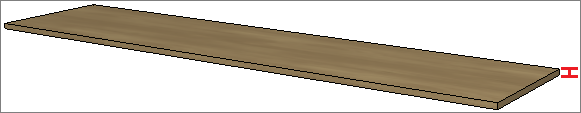

Special

A - Panel maximum width: defines the maximum width of the panel to be used in the fabrication of the module side.

B –Panel Maximum lenght: defines the maximum plate length to be used in the manufacturing of the module's side.

C -Panel Thickness: defines the thickness of the plate to be used in the manufacturing of the module's side.

Components

Cleats

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Kick Plate

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

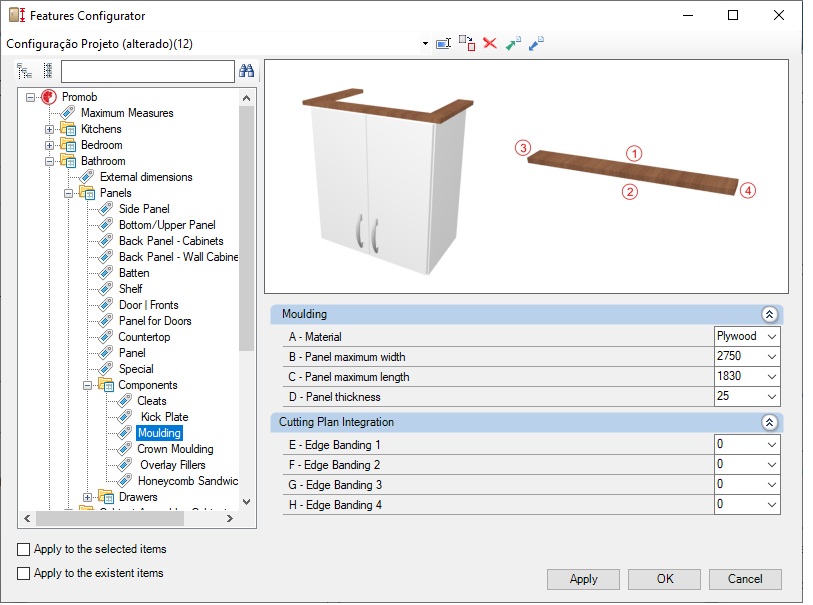

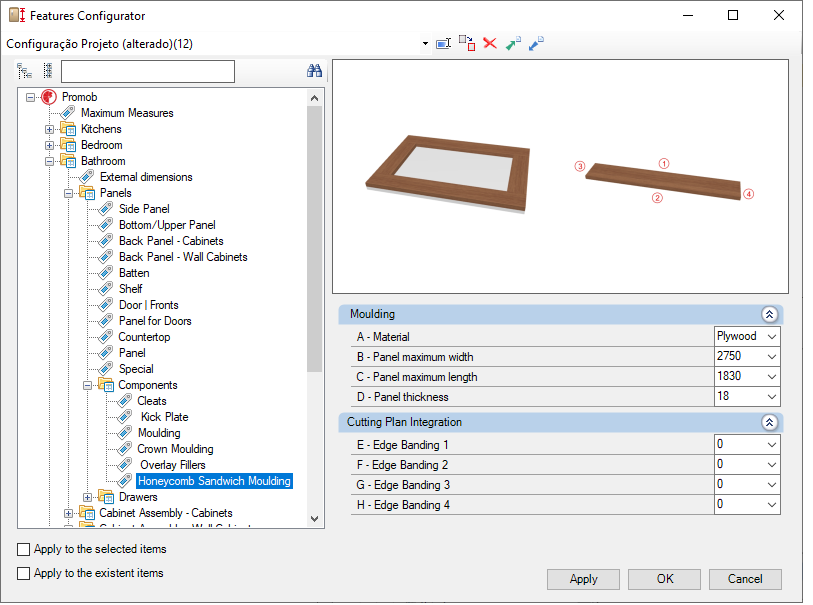

Moulding

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

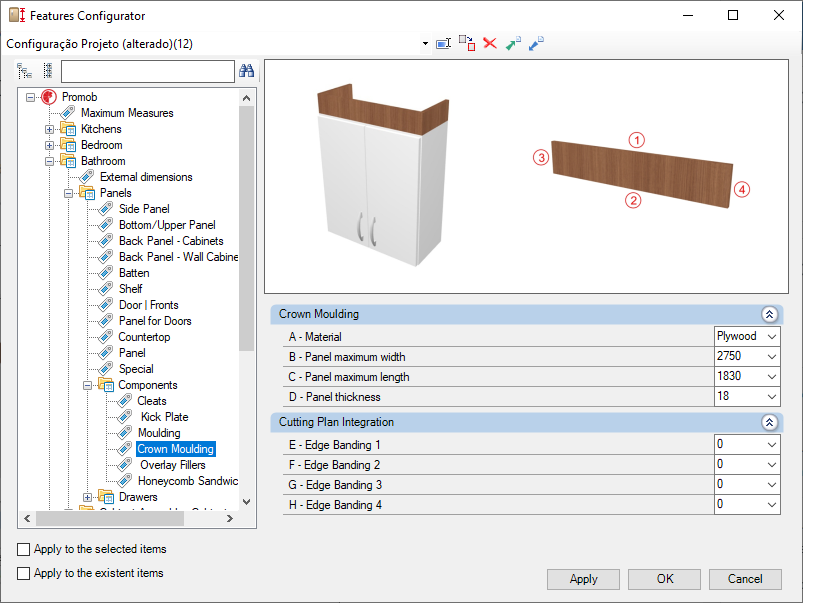

Crown Moulding

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

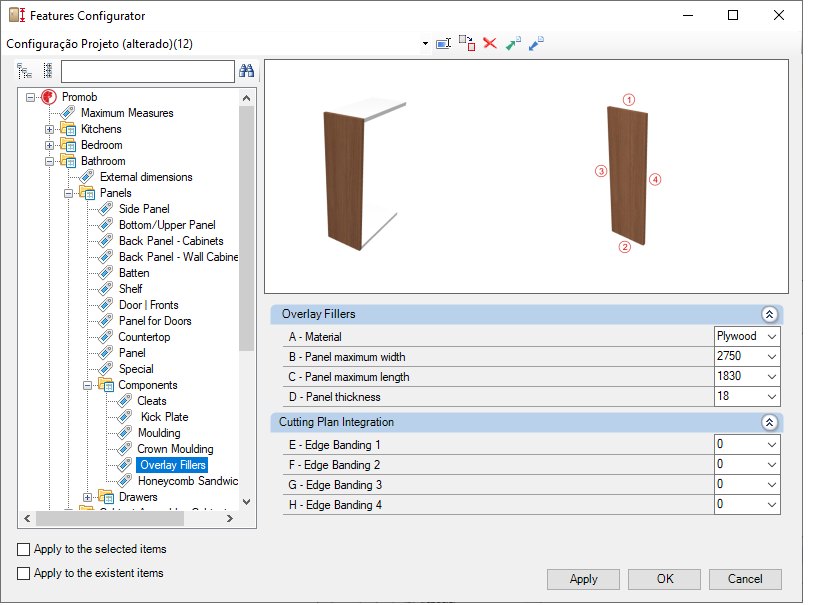

Overlay Fillers

Cutting Plan Integration

E - Edge Banding 1:for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Honeycomb Sandwich Moulding

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Drawers

Side Panel

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3:for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Front Face

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Fita Borda 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Back Panel

Cutting Plan Integration

E - Edge Band 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3: for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.

Bottom Panel

Cutting Plan Integration

E - Edge Banding 1: for cut plans that read the thickness of the edge band, set the thickness to side 1.

F - Edge Banding 2: for cut plans that read the thickness of the edge band, set the thickness to side 2.

G - Edge Banding 3:for cut plans that read the thickness of the edge band, set the thickness to side 3.

H - Edge Banding 4: for cut plans that read the thickness of the edge band, set the thickness to side 4.