Check below the specifications and configurations available in the Insider FT2 plugin.

Available from version: Plugin Builder 1.60.17.4

Machine Type: CNC Machining Center

Manufacturer: Biesse

Example programs: BOT0133A

Generated file extension: .XNC

Main features

- Drilling;

- Milling;

Settings

To check the settings on CNC Machines, click here.

Machine 1

General

Name: define the name for the machine;

IMPORTANT: The name set in this field also changes the name of the folder where the generated files will be saved.

Length X (mm): the value entered in this field indicates the maximum usable length of the machine;

Width Y (mm): the value entered in this field indicates the maximum usable width of the machine.

Several

Program format:the format defined in this field will define the extension of the generated file: .bpp , .Cid or .Cix.

Tools

To check the settings about CNC Tools, click here.

Saws

Saws are used to make slot.

Properties

Alignment: alignment of the saw, center, left or right;

Diameter (mm): tool diameter;

In offset (mm): transfer between the passes of the hardware to avoid leftover material;

Name: the name defined in this field must match the registration defined on the machine so that the tool can be located correctly;

Out offset (mm): saw output compensation for performing the cut, in millimeters. This setting is only applied if the slot ends outside or on the endpoint of the part;

Overlap (mm): input compensation of the saw to perform the cut, in millimeters. This setting is only applied if the slot starts outside or on the starting point of the part;

Thickness (mm): thickness of the saw.

Restrictions

Maximum thickness of the saw:Maximum thickness of the saw, in millimeters;

Minimum thickness of the saw: Minimum thickness of the saw, in millimeters.

Setups

General

Name: the name set in this field also changes the name of the folder where the generated files will be saved;

Alignment by face: defines whether the alignment face registered on each part is considered when generating programs. If yes, this face will be aligned according to the selected configuration. For more information click here;

Simmetry: execute symmetrical holes simultaneously;

Version: version of the generated program. It must be compatible with the software that will open the files generated by the plugin.

Machine

Priorization order: defines the order of prioritization of operations for program generation. According to the order indicated in this field, the plugin will prioritize, in program A, the selected option;

Example: In a part that has holes on one side and tears on the other side, the order indicated in this field will determine which of them will be prioritized in the A program.

Operations ordering: order that the machine performs operations;

Example: in a part that has holes and tears on the same face, the order indicated in this field will determine the sequence in which they will be executed by the machine.

Holes

Drill bits for blind hole operation: option for normal drilling. Normal drilling is considered normal when it is not through or marking drilling;

Minimium diameter to use Forstnet Bit (mm) | normal drill (mm): this option will only be available when Normal Drill is chosen in the Normal Drill option. Drillings with a diameter smaller than the one registered will use a normal drill. Drillings with diameter greater than or equal to the registered diameter will use a large normal drill;

Drill Bits for through hole operations: type of drill for through hole drilling - Normal Drill, Spear or Reaming Drill;

Drill bit for marking hole operation: type of drill bit for marking drilling – Normal Drill, Lance, or Reamer;

Depth of marking hole operation (mm): maximum depth to be a marking hole. When the hole is smaller or equal it will automatically be considered a marking hole;

Drill bit angle used in through holes: determine the drill bit end angle for through hole usage (from 25 to 90 degrees). This value is used in the calculation to determine the increment in the through-hole depth to ensure that the hole passes completely through the part;

Drill GAP in through hole operation (mm): determine the clearance of the drill for use in through holes;

Drill Bits Type: defines the codes used for each drill type. The codes are defined in the fields, reamer drill type, lance drill type, normal drill type, and large normal drill type;

Number of horizontal drill bits (X): the number of drills, for each horizontal face, present in the machine;

Number of lateral drill bits (Y): number of drill bits, for each side face, present in the machine;

Number of vertical drill bits (Z): number of vertical drills present in the machine.

Technical Data

Maximum thickness(Z): maximum thickness of the part that the machine can perform operations;

Minimum length (X): minimum thickness of the part that the machine can perform operations;

Minimum thickness (Z): minimum thickness of the part that the machine can perform operations;

Minimum width (Y): minimum part length for the machine to perform operations.

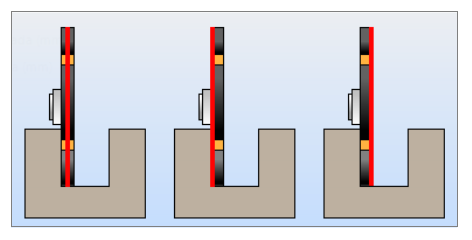

Example Technical Drawing