For these machines, the part positioning information for the machine can be sent to the ERP Integration XML or cutting plan file.

This information tells the operator in which orientation the part must be positioned on the machine's conveyor belt, according to the program generated by the CNC Plugin.

Configuration

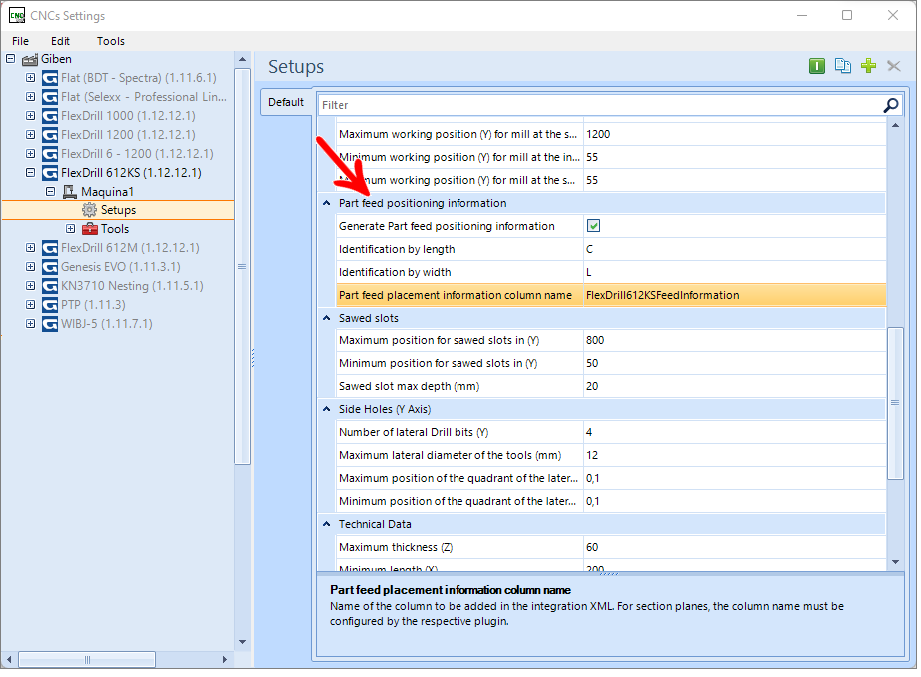

This functionality must be configured through 4 fields available in the CNC Setup of the machines:

- Generate Part feed positioning information: when you check this option, the information for feeding the part to the machine is sent to the integration XML and to the respective column in the cut plan file. IMPORTANT: You need to add the column in the File menu settings of the desired cut plan plugin. The generated information is according to the following two options, depending on the part orientation.

- Identification by length: value sent when the part is to be fed with the length (largest dimension) in the direction of the machine's belt.

- Identification by width: value sent when the part must be fed with the width (smallest dimension) in the direction of the machine belt.

- Part feed placement information column name: name of the column to be added in the integration XML. For cutting plans, the column name has to be set by the respective plugin.

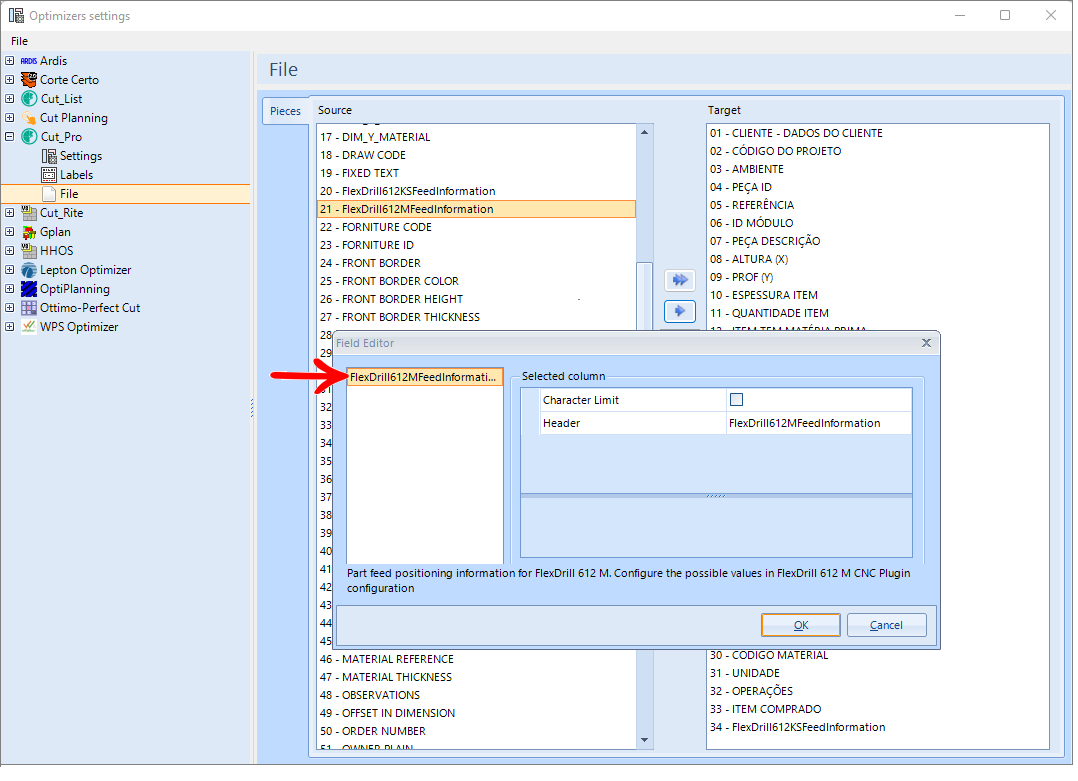

Sending the information

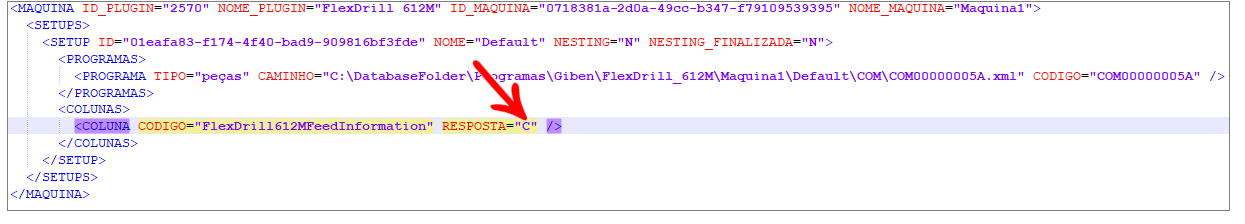

To send the information to the cut plane Optimizer files, you must also add the column in the configuration of the desired Optimizer plugin, the column is identified with the default Header value, FlexDrill612KSFeedInformation and/or FlexDrill612MFeedInformation depending on the desired plugin.

Examples

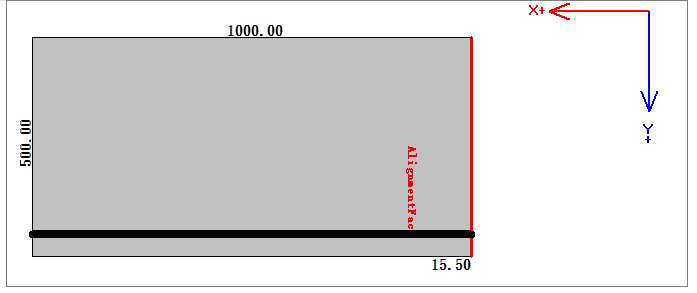

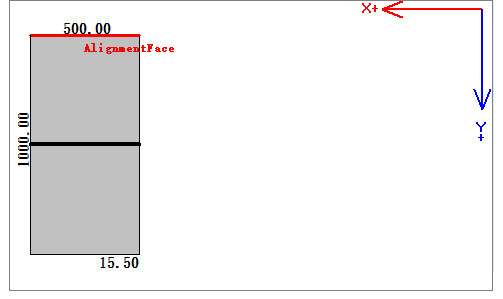

Consider the following two programs, the programs were generated in different orientations, so they need to be positioned differently on the machine.

- Program 1:

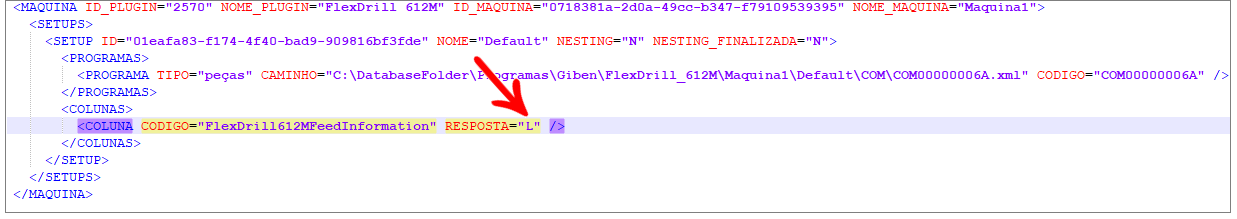

- Information in XML for Program 1:

- Program 2:

- Information in XML for Program 2: