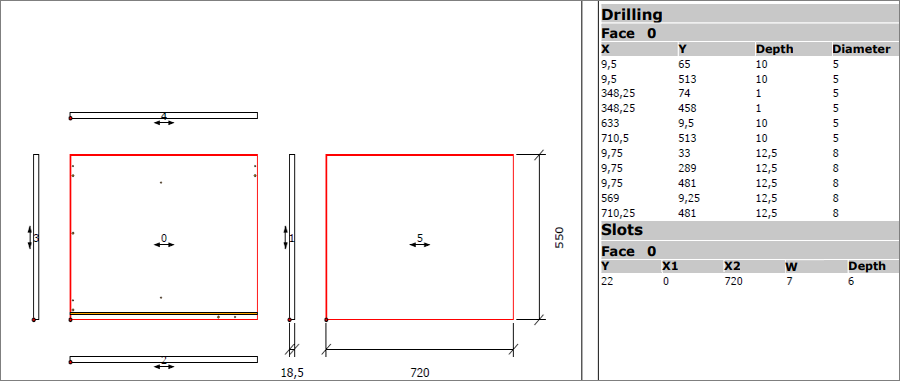

In this article, an example will be presented to calculate the Channel and Drill operations. The part below was used as an example:

Channel and Drill Operation

| DATA TO FILL OUT | ||

| Channel and Drill operations information filled in from the drilling center | ||

| Standard part channel length (mm) | 720 | Millimeters |

| Production capacity of the standard part in the month (un) | 2.037 | Units |

| Number of holes in the standard part (un) | 11 | Units |

| Time to put the part on the machine (s) | 20 | Seconds |

| Standard part channel production time (s) | 60 | Seconds |

| Production time of standard part holes (s) | 150 | Seconds |

| Time to produce 1 channel pattern piece + holes in month (s) | 230 | Seconds |

| Worked days | 22 | Days |

| Shifts worked | 1 | Shifts |

| Actual hours worked per day (h) | 6 | Hours |

| Hours worked per month (h) | 130,16 | Hours |

| Hours per day worked (h) | 8 | Hours |

| Machine cost per month | R$ 5.000,00 | Reais |

| Standard part channel cost R$ | R$ 0,70 | Reais |

| Cost of standard part holes R$ | R$ 1,75 | Reais |

| Standard part cost R$/unit | R$ 2,45 | Reais per unit |

| CHANNEL OPERATION VALUE R$/M | R$ 0,97 | Reais per meter |

| VALUE OF THE HOLE OPERATION R$/UN | R$ 0,16 | Reais per unit |

Edge band Operation

| DATA TO FILL OUT | ||

| Operation Information Edge Band from edge banding machine | ||

| Displacement time (s) | 60 | Seconds |

| Machine downtime in the day (minutes) | 180 | Minutes |

| Table length to apply edge (mm) | 1.500 | Millimeters |

| Average space between pieces to be edge banding (mm) | 200 | Millimeters |

| Machine cost per month | R$ 4.500,00 | Reais |

| Worked days | 22 | Days |

| Hours worked per day (h) | 8 | Horas |

| Shifts worked | 1 | Shifts |

| Actual hours worked per day (h) | 5 | Hours |

| Hours worked per month (h) | 110 | Hours |

| Seconds worked in month (s) | 396.000 | Seconds |

| Time to edge banding 1 meter (s/m) | 545.455 | Seconds per meter |

| Capacity of meters cut month (m) | 7.260 | Meters |

| CHANNEL OPERATION VALUE R$/M | R$ 0,62 | Reais per meter |

Cut Operation

| DATA TO FILL OUT | ||

| Cutting operation information from the disconnector | ||

| Displacement time (s) | 55 | Seconds |

| Machine downtime in the day (minutes) | 120 | Minutes |

| Cutting table length (mm) | 2.800 | Millimeters |

| Machine cost per month | R$ 5.000,00 | Reais |

| Worked days | 22 | Days |

| Hours worked per day (h) | 8 | Hours |

| Shifts worked | 1 | Shifts |

| Actual hours worked per day (h) | 6 | Hours |

| Hours worked per month (h) | 132 | Hours |

| Seconds worked in month (s) | 475.200 | Seconds |

| Time to cut 1 meter (s/m) | 196.429 | Seconds per meter |

| Capacity of meters cut month (m) | 24.192 | Metros |

| CHANNEL OPERATION VALUE R$/M | R$ 0,21 | Reais per meter |

Polycut Cut Operation

| DATA TO FILL OUT | ||

| Information on the cutting operation for Policorte (profile cutting) | ||

| Time per cut(s) | 10 | Seconds |

| Time to place the part on the machine(s) | 120 | Seconds |

| Machine downtime in the day (minutes) | 200 | Minutes |

| Machine cost per month | R$ 2.000,00 | Reais |

| Worked days | 22 | Days |

| Hours worked per day (h) | 8 | Hours |

| Shifts worked | 1 | Shifts |

| Actual hours worked per day (h) | 5 | Hours |

| Hours worked per month (h) | 102 | Hours |

| Seconds worked in month (s) | 369.600 | Seconds |

| Time to make 1 cut (s/un) | 13.00000 | Seconds per unit |

| Cutting capacity per month (m) | 2.843,07 | Units |

| CHANNEL OPERATION VALUE R$/UN | R$ 0,70 | Reais per unit |