Available from version:

- Plugin Builder - 1.12.12.16 or higher

Slots and machining that have a milling cutter as a tool, and this milling cutter has an input or output extension greater than zero in the register, will have the treatment of descending or rising in a ramp applied in the generation of programs.

There is a specific treatment for internal and external machining, being the descent applied at the entrance of the cutter during machining and the rise at the exit of the cutter during machining.

In order for the ramp down treatment to be applied to a tool path or slot, the input type must be Ramp and the Input Elongation (mm) field must be greater than zero. For a ramp ascent, the output type must be Ramp and the Output extension (mm) field must be greater than zero. Thus, the machining processes receive an input or output command corresponding to the cutter diameter and the registered extensions.

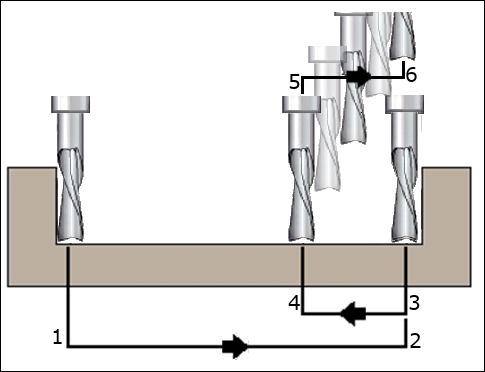

Operation in external machining

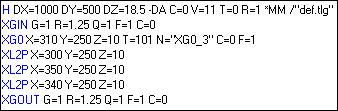

Machining that starts on the outside of the part receives a descent starting before machining, input applied at the beginning of machining, after entering the part, the cutter travels to the end of machining, making all the necessary cut.

EXAMPLE:

Input - Machining starting outside the part

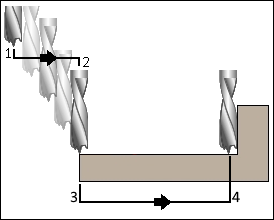

For outputs, the concept applied is the same as used for inputs. The output is after machining.

Output - Machining with output outside the part

Operation in internal machining

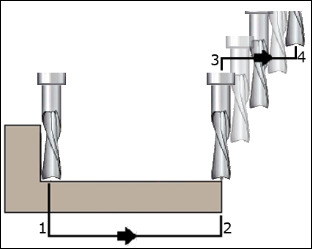

Machining that starts inside the part receives a descent starting at the top of the machining, input applied after the start of machining, after entering the part the cutter travels to the beginning of machining, then travels to the end making all the necessary cut.

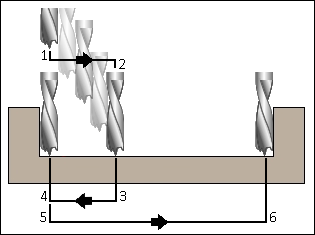

For the output, a setback occurs on top of the machining, thus ensuring the integrity of the part.

EXAMPLE:

Entry - Machining with the start within the part

Output - Machining with an end within the part

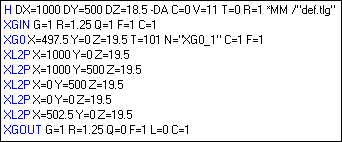

Programs Example

External machining program

Internal machining program