Working Areas consist of dividing the table of a machine into specific areas. Facilitating the work of the machine operator, reducing the work field, positioning the work stops, and organizing the parts.

NOTE: Access to edit the fields of this configuration is restricted, which requires a password to access. If you need to change the information in the fields, communicate with the Promob Support

This article covers the following topics:

Working Fields

The dimensions of the working fields (Working areas) may vary on each machine, as well as the name of the fields. Below is an example of standard fields on the Prátika 310 machine:

- A - Back left

- D - Right back

- I - Left center

- L - Right center

- Binaries - AD and IL

- 00 - By default, it is later and treated as a single field.

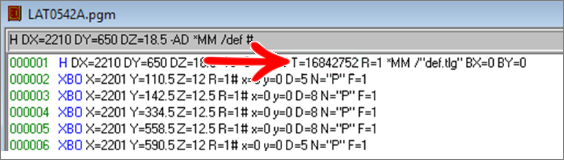

T Codes

The T codes are codes contained in the configuration of some machines from the manufacturer SCM.

These codes command the activation of the stops to position the part. There are stops in the individual area and in the combined area, where the type of each area can be configured through the machine plugin.

Check the codes:

- T for field with binary area = 16842752

- T for field with the binary area with cargo help = 16842753

- T for field with individual area = 65536

- T for field with individual area w/ cargo help = 65537

The loading assistance is a kind of ruler with pneumatic actuation (just like the stops), in which the part slides more easily on the machine table, the activation of the same is done by the program.

This command goes to the program with the variable T, when the part is larger than the individual area, it uses the code of the combined area (if configured), if smaller, it uses the individual area, example below:

Working areas without pendulum

Working without a pendulum consists of working with only one piece at a time on the machine, in this case, the working areas are configured as shown below, in the fields of the Pratika 310 machine, where each area receives a certain piece size.

I Field

In this case, the work area will receive pieces measuring 1390 mm wide by 600 mm deep.

IL Field

In this work, the area will be sent the pieces with measures of 3050 mm in width by 600 mm in length.

AD Field

This work area consists of the total size of the machine table, where parts with a maximum size of 3050 mm wide by 1252 mm deep will be shipped.

Working area with pendulum

When working with pendulum work areas, the user is able to use two areas of the machine simultaneously, that is, while the machine performs operations on a part, the operator is able to position the part in the indicated work area. Below is an example of fields from the Tech Z1 machine.

00 Field

In this case, we have work area 00 where pieces with a maximum size of 1390 mm wide by 1050 mm long can be placed.

AD Field

In this area, the part may have a size equivalent to the size of the machine, that is, 3050 mm wide by 1050 mm deep.

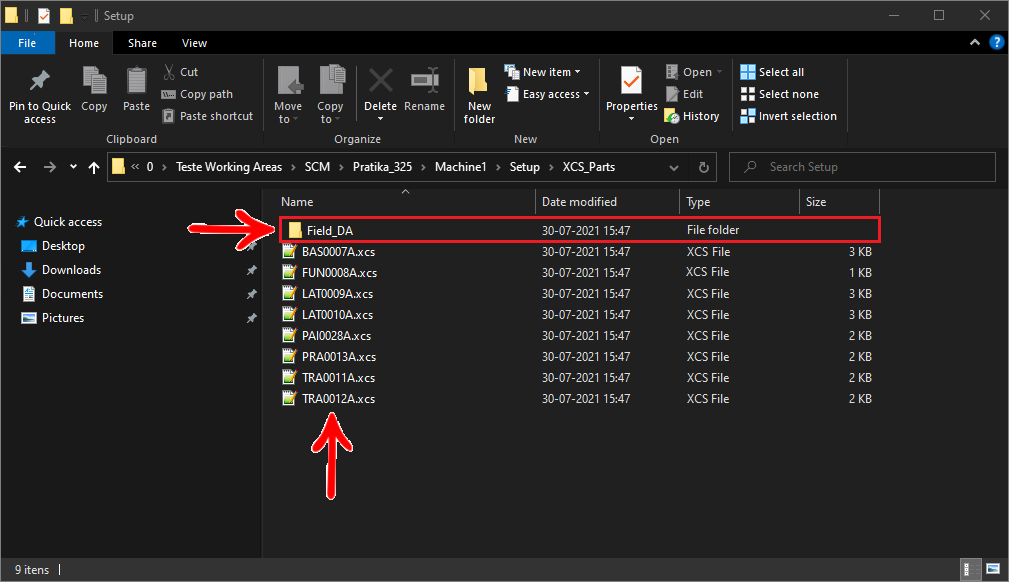

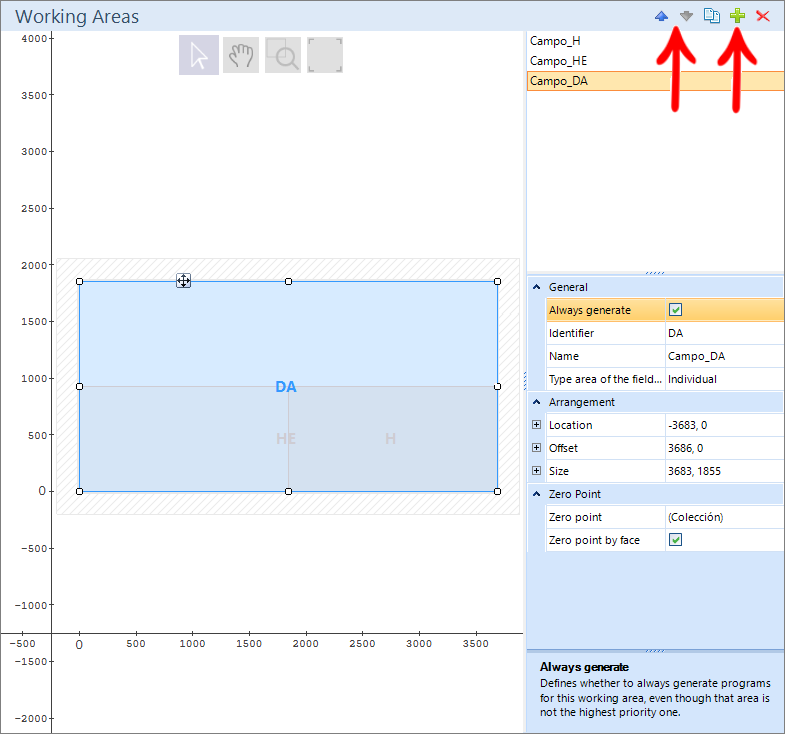

File Generation

and after, define the priority of each one, through the arrows.

and after, define the priority of each one, through the arrows.

Working field B: Priority 2, 15 operations can be performed

Result: Working field A will be used, as it has priority 1.

Working field B: Priority 2, 20 operations can be performed

Result: Working field B will be used, as it performs more operations than Work Area A.