The overcut indicates how much more the part should be sent to the cut, adding to its design measure.

EXAMPLE:

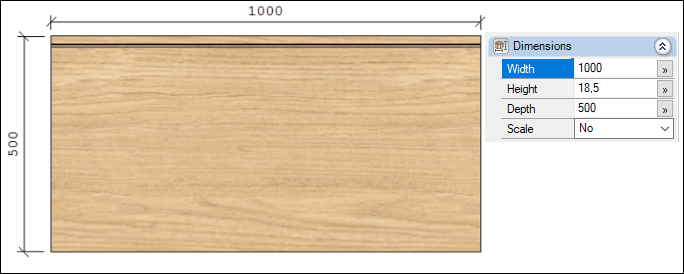

In Promob the piece size is 1000x500 (final size).

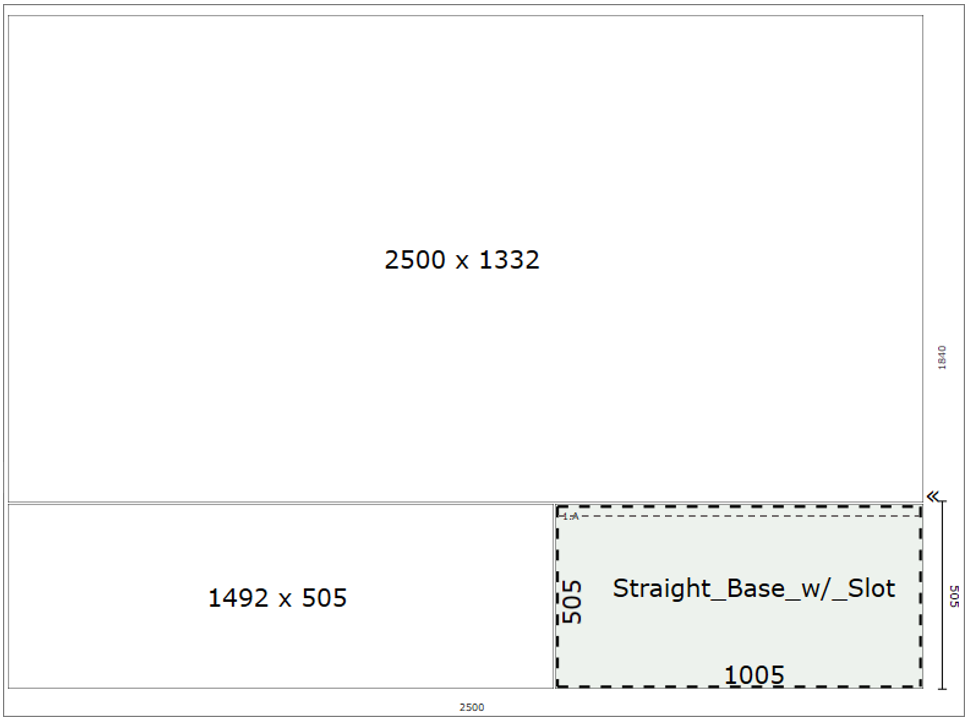

Applying a 5mm overcut in X and Y, the piece will be cut 1005x505.

Promob Studio (design)

Cut Pro (cut plan)

Panel overcut is typically used on parts that will need to be trimmed, such as wood hollow panel or composite top parts. Because due to the gluing of the pieces, they will be able to move, so with the overcut and the subsequent recut, the size used in the design is guaranteed.

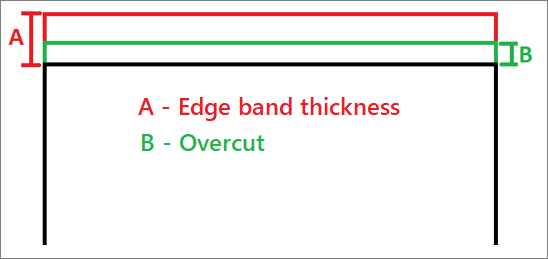

The same concept is applied for panel overcut in edge band application.

In the case of edge band, it must be taken into account if the material is removed from the piece before applying the tape (gluer with entry router) since the cut size of the piece does not take into account the thickness of the edge tapes.

Scenery 1:

- Edge gluer with a router that will remove 1mm;

- 1mm edge band;

The overcut should be 1mm, so that the 500mm-deep part in the design, at the end of the production process, remains with 500mm.

Scenery 2:

- Edge gluer with router that will remove 3mm

- 1mm edge band;

The overcut should be 2mm, thus 500mm (design) + 2mm (overcut), sent to the 502mm cut.

The router will remove 3mm, 499mm, 1mm edge band application, final size 500mm as per the design.

Scenery 3:

- Manual tape application – no router;

- 1mm edge band;

The overcut should be 0 as there will be no material removal, only addition (edge band). So the cut of the piece will be 499mm so that when you have the edge band it will have 500mm according to the design.